Turning Liquid Into Glass: The Quiet Revolution at Hanford

In southeastern Washington, spread over 580 square miles, the Hanford Site was once the heart of America’s plutonium production machine. Bet that’s a sentence you weren’t expecting to read today.

Between 1943 and 1987, nine reactors, five large re-processing “canyons” and hundreds of support facilities churned out plutonium by the ton. They built bombs here, boxes of plutonium, and tanks of waste, it was a legacy of war, secrecy, and danger.

Now, decades later, a plant rises where this destruction once roared to life, and it’s not about making power. It’s about stopping the damage. Today the site holds a monolith of 177 underground storage tanks, some single-walled, some double. They’re aging, cracked, and leaking. These tanks currently store roughly 56 million gallons of radioactive and chemical waste.

Many of these tanks were designed for 20-40 years, and some have been there for about 70 years now. Leakage has been going on for a while now, with more than a million gallons estimated to have seeped into the ground.

The cleanup cost is estimated at $300 billion-$640 billion and counting.

The task at hand is helping hold back what might otherwise reach the Columbia River, the soil, the air, the wildlife, and the people who live nearby.

What Glass Has to Do with It

Enter the Department of Energy (DOE) plan to transform liquid, highly-radioactive waste into a stable, inert form: glass. The technology is called vitrification.

Basically, waste is separated into two different piles: “low-activity” and “high-level”. Glass-forming materials (like silica, boron oxide, aluminum oxide, sodium and calcium oxides, and iron, magnesium, and zirconium compounds in case you were wondering like I was) are added to the waste mixture.

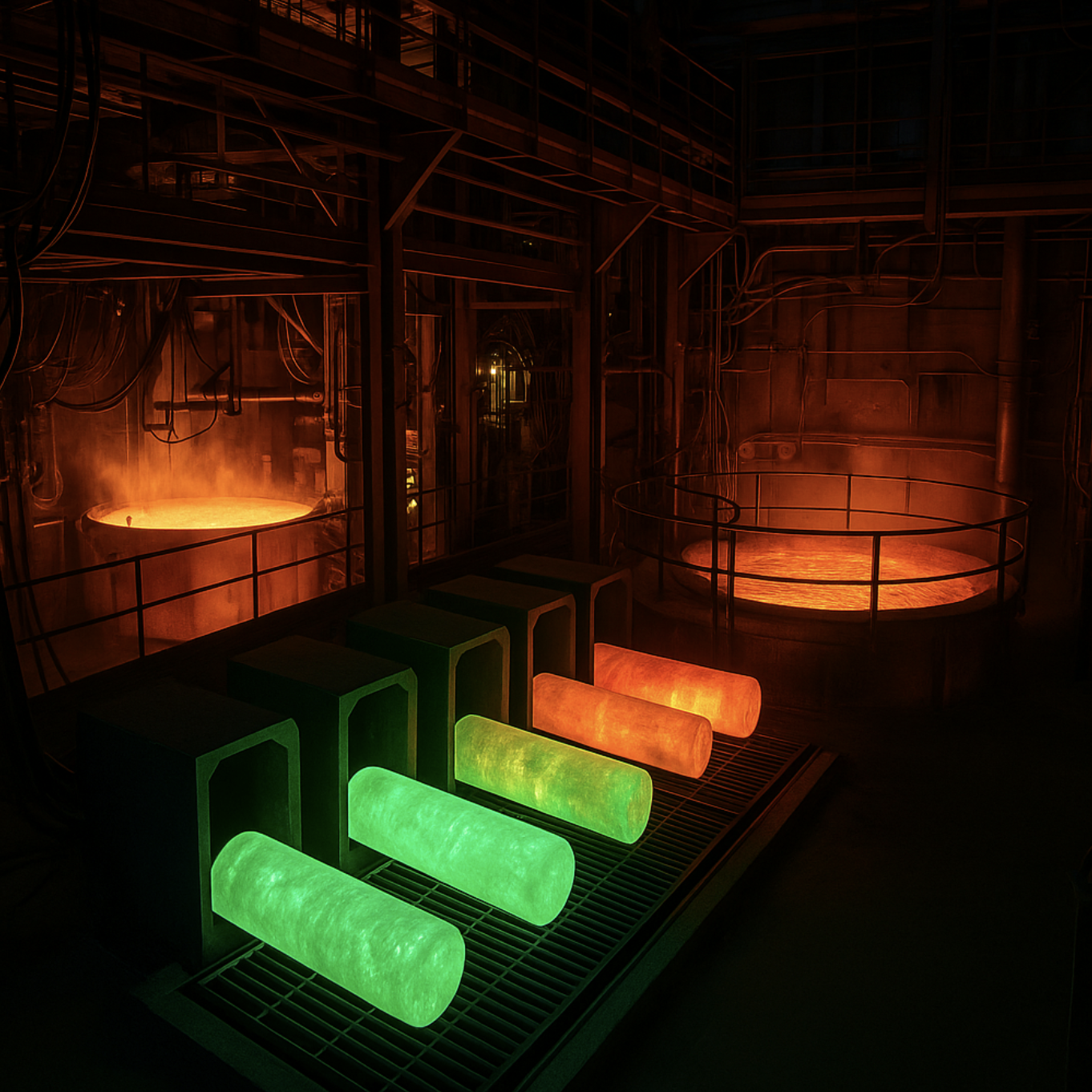

The mixture of all that good stuff is then heated to approximately 2,100 °F (~1,150 °C) in melters, which are massive molten crucibles (had to look it up).

The molten “waste-glass” is poured into stainless steel canisters and allowed to cool and solidify. The result of all this effort is a log of glass, radioactive still, but locked-in at least, and impervious to most environmental decay.

The centerpiece of this wild transformation is the Waste Treatment and Immobilization Plant (WTP or “Vit Plant”), which is arguably the largest radioactive-waste treatment facility ever built. The plant occupies some 65 acres and houses three major facilities the Low‐Activity Waste (LAW) Facility, an Analytical Laboratory, and a High‐Level Waste (HLW) Facility.

They call it “turning liquid into glass,” but what it really is is turning a whole big mess into something we hope won’t break.

The Scale, the Risk, the Atlas Shoulders

I love a good challenge, and this is exactly that.

Tanks hold between 55,000 and 1.2 million gallons each. One leak from a tank can be one million gallons into the soil, which as I mentioned already is already a reality we’re facing.

The cleanup timeline stretches into decades, this isn’t a short-term goal at all. October 2025 is cited for the first phase of vitrification.

Also, to make things a little more fun (because it wasn’t already), costs keep rising. To finish everything could cost six hundred billion dollars or more. That’s not a number, that’s a scale so large I’m not sure we’ll see any movement in our lifetime.

At the core of all of this, there are melters the size of swimming pools, fed one bucket of radioactive soup at a time, heated like hell, then poured into logs, before being put away, “safe for thousands of years.”

Because when you deal in half-lives and isotopes, decades become minutes at 1,150 °C, but the outcome lasts centuries.

Progress, But Not Finished

Construction of WTP began many years ago. Delays, cost-overruns, safety hurdles have plagued it and pushed it back and back, but as of 2024-25, real milestones are being hit finally. The DFLAW (Direct-Feed Low-Activity Waste) approach is being commissioned, test melters reached 2,100 °F, and new stack and scrubber studies are underway to be sure that emissions remain within safe bounds.

For some perspective as well, don’t forget the Columbia River flows nearby. The tribes, fishers, plant-gatherers, all the people nearby still depend on this environment. If tanks leak, contamination spreads downstream to the heart of all of them.

These sort of projects are the result of all the secrecy of the cold war. The Manhattan Project needed secrecy, speed, and production, and the entire world felt the results of it. Decades later, the cost of all that urgency falls to the land, the public, and even our future generations.

A log of glass will outlast skyscrapers, cities, maybe a hundred human civilizations. If they fail, failure becomes our legacy, with a persistent poison we can’t outrun.

Don’t forget about the true hero’s of this whole operation, the engineers and the people who make it happen.

Workers in hazmat suits, engineers watching melters, tribal representatives demanding accountability, scientists testing materials, the list goes on and on and might even contain Greta Thunberg for all we know.

At the Vit Plant: 3,000+ team members working shift after shift to ensure the system is safe.

The past workers at Hanford have had many reported exposure to vapors, radiation, and uncertain futures that can make anyone who’s watched Chernobyl nervous.

The site itself has turned into a voiceless pivot from creator of destruction to containment.

A Loud Lesson

As a person who just loves irony in this life, I love the idea that the plant that stabilized production is now processing the waste from production. The same land that made those horrible weapons is now trying to unmake the threat those weapons left behind.

Because, in my opinion, that no one asked for, there’s always a balance in this life. If you are creating weapons of mass destruction it hurts you as much as the people you use them on in the end, in some way/shape/or form.

It’s not glamorous to bury radioactive waste, and I would personally want nothing to do with that job. It doesn’t show up in headlines the same way bombs do either, but maybe it should. Because making the world safer isn’t just about making better toys, it’s about cleaning up after the ones we already made.

This is one of the most complex cleanup missions in human history, outlasting wars, technologies, budgets, and even governments. It’s not about speed anymore; it’s about endurance.

And I’m interested to see where it goes next and how successful it is.

Other Reads You Might Enjoy:

The Kyshtym Disaster: The Nuclear Catastrophe the USSR Tried to Erase

Space Power, Super Panels, and the Future of Global Energy: Japan’s Wild Leap Toward Sci-Fi Reality

When the Atom Breaks Twice: What Happens When Nuclear Sites Are Bombed

Rebuilding the Ocean’s Bones: How 3D Printing Is Saving Australia’s Coral Reefs

The Fabric That Feels: How Scientists Created Touch-Sensitive Clothing Without Electronics

The Concrete That Heals Itself: How Synthetic Lichen Could Reshape Our World

The Earth’s Core Is Leaking Gold: A Hidden Alchemy Beneath Our Feet

The Floating Magnet That Shouldn’t Exist: Why This Levitation Experiment Is Rattling Physics